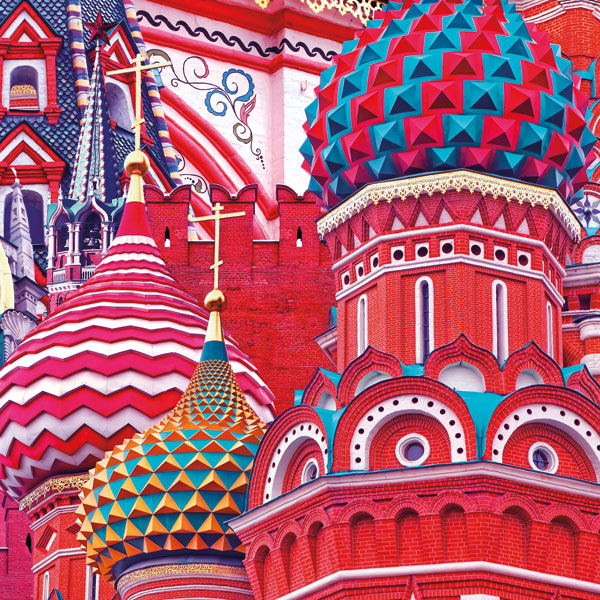

Understanding cultural differences is fundamental to the establishment of solid interpersonal relations with local partners. For the Maire Tecnimont Team, which is working hard to develop the Russian plant in Amurski, intercultural know-how is a key element for successfully blending a heterogeneous team, composed mainly of Russians, Italians and Chinese. The experience of a multinational that works daily with engineers and technicians from around the world can help us understand that at least three quarters of the planet thinks very differently from us.As westerners, we are used to reasoning and acting individually, rather than collectively. A few small examples? Russian managers prefer not to shake hands at the entrance of a meeting room as it is considered bad luck. During meetings, they speak in hierarchical order: first the CEO and then all the others. And don’t take your jacket off during negotiations, it could be interpreted as a sign of disrespect.

Amurski is a major project in the Amur Region (in the far Russian East, on the border with China) where Maire Tecnimont will lead a consortium with Chinese partner Sinopec, to build a plant capable of treating gas and routing it directly into the pipelines headed towards China. This activity represents an exponential step forward for the Group. “Our colleagues on the task force,” explains Carlo Nicolais, Director of Institutional Relations and Communications, “are witnesses of the degree to which engineering is a profession that leads one to experiment with cultural diversities, rescaling the alleged unique nature of western values with regard to the rest of the world. Indeed, this impacts daily project activities, driving the adaptation of words and communication codes in an intercultural process on the field.”

The project task force includes over 900 engineers, specialized in a variety of areas, who will be working in 17 operative centres across 10 time zones, ranging from Milan to Mumbai and from Moscow to Ningbo (China). The project also involves 12 design institutes from Saint Petersburg to Blagovenschensk to the Svobodny site. All of these elements give you an idea of the magnitude of the challenge faced by Maire Tecnimont management, at work in Amurski on a vast project.

Besides its economic dimension (the 3.9-billion-euro agreement is the largest ever undertaken by the Group), the project is also important on account of its location. We will be the only Italian company operating in that corner of Asian Russia. “We were selected on account of our profound understanding of the Russian market,” explains Chairman Fabrizio Di Amato, “and our engineering and developmental know-how in complex areas. We are perceived as an international company with a strong local presence.” In fact, the contract signed with the Gazprom Group includes detail engineering, procurement, construction work, pre-commissioning and commission of utilities, off-sites and infrastructure.

The real novelty of the project in Amurski is represented by the sheer size of the project and its numbers. Pierroberto Folgiero, the Group CEO, points out “the work site for the plant, which will be constructed near the City of Svobodny in the Amur Region, occupies 850 hectares. It will be the largest gas treatment plant in the world and will have the potential to process 42 billion cubic metres of gas per year, which, once extracted, will be used to produce fuels, fertilizers and plastics.”

Overcoming Issues and Prejudices

Coming back to our colleagues on the task force, during the construction of the plant, the nearly sixteen thousand individuals involved will populate a city-site with significant issues concerning logistics and supplies. The temperatures range from 40 degrees below zero in the winter to 40 degrees above zero in the summer. The area is completely surrounded by the Siberian tundra for thousands of kilometres. Moscow is nine hours and six time zones away by airplane.

Maria Selli, Maire Tecnimont Project Director for Amurski, explains “The behind the scenes of such a complex activity as the construction of a gas treatment plant in the Far East, on the border with China, tests individuals from a climactic, geographical and linguistic point of view. Soft skills make all the difference. The ability to adapt without becoming passive and reacting every minute to sudden changes is paramount. It is not always possible to speak in English, but as I often say, this contract is a fantastic test bed. Notwithstanding the fact that we will be operating at breakneck speeds, once completed, this [project] will open up important new opportunities for our Group. And we will be far richer both culturally and humanly.”

It is not easy to adapt the different communication codes of westerners and Russians. The former Soviet Union is a country divided between tradition and innovation, between formal and bureaucratic communication and the rapid rise of social networks. People do not imagine that in the backstage of business with East European partners, there is a vast world of intercultural relations. “The key is perseverance,” concludes Maria Selli. “One must arrive in a different country leaving behind one’s baggage of prejudices and stereotypes, which are related to our ways of thinking and our reference cultures. We need to profoundly understand the habits of others and show up for the first meeting with particular attention to our style. We must be sober, elegant and punctual – for Russians this is a sign of consideration and respect. Our language, climate and homelands, as well as our family and social contexts, even the food we eat, are all elements that mould our beliefs and contribute to shaping the ways in which we conduct international business, overcoming prejudices and issues.”